- Products

- Global Network

-

Technical

Information- Technical Information Top

-

How to use chip resistors smartly

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

- 8.Various methods of current sensing and advantage of current sensing resistors

- 9.Application and recommended usage of current sensing resistors

- Smart usage of High Frequency Chip Components

- Application Information

-

Product Technical Report

Standard Specification for surface mount chip resistors

- Recommended land patterns

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

Standard Specification for High frequency surface mount components

- Recommended reflow soldering profile

- Dimensions of the packaging tape

- Dimensions of the packaging reel

-

Technical FAQ

High Precision Thin Film Chip Resistors

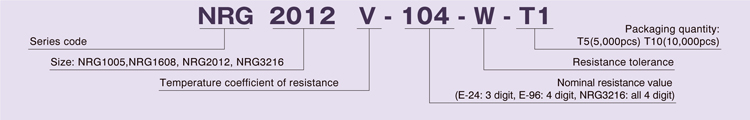

- ・Part numbering

- ・Performance characteristics

- ・Quality, reliability

- ・Mounting, packaging

Current sensing chip resistors

- ・Part numbering

- ・Performance characteristics

- ・Quality, reliability

- ・Mounting, packaging

- Company Profile

-

QC and Environmental

Activities

Thin film surface mount resistors

A non-magnetic materials used.

Non-magnetic metal thin film chip resistors NRG series

- Lead free

- Halogen free

- RoHS Compliance

- High Reliability

- High Precision

- AEC-Q200 Compliant

- High-temperature operation

- High power

- High voltage

- Anti-surge

- Non-magnetic

- High-Resolution Audio

- Anti-sulfur

- trimmable

- leads

NRG - Contents

NRG - Features & Applications

Features

- Thin film chip resistors using non-magnetic materials

- Long term stability with inorganic passivation

- High precision resistance tolerance: ±0.05%, very small TCR: ±5ppm/℃

- Thin film structure enabling low noise and anti-sulfur

Applications

- Medical electronics, industrial measurement instrumentation

- equipment/devices under magnetic field

NRG - Specifications

◆Part numbering system

◆Electrical Specification

| Type | Power ratings |

Temperature coefficient of resistance |

Resistance range(Ω) Resistance tolerance |

Maximum voltage |

Resistance value series |

Operating temperature |

Packaging quantity |

||

|---|---|---|---|---|---|---|---|---|---|

| (ppm/℃) | ±0.05%(W) | ±0.1%(B) | ±0.5%(D) | ||||||

| NRG1005 | 1/16W | ±5(V) | 100≦R≦3k | ー | 75V | E-24, E-96 |

-55℃ ~155℃ | T5 T10*1 |

|

| ±10(N) | 47≦R≦100k | ||||||||

| ±25(P) | 47≦R≦150k | ||||||||

| ±100(R) | ー | 10≦R≦47 | |||||||

| NRG1608 | 1/10W | ±5(V) | 100≦R<5.1k | 100V | T5 | ||||

| ±10(N) | 47≦R≦270k | ||||||||

| ±25(P) | 47≦R≦270k | 47≦R≦332k | 47≦R≦360k | ||||||

| ±50(Q) | ー | ー | 10≦R<47 | ||||||

| NRG2012 | 1/8W | ±5(V) | 100≦R<10.2k | 150V | |||||

| ±10(N) | 47≦R≦475k | ||||||||

| ±25(P) | 47≦R≦475k | 47≦R≦1M | |||||||

| ±50(Q) | ー | ー | 10≦R<47 | ||||||

| NRG3216 | 1/4W | ±5(V) | 100≦R<33.2k | 200V | |||||

| ±10(N) | 47≦R≦1M | ||||||||

| ±25(P) | 47≦R≦1M | ||||||||

| ±50(Q) | ー | ー | 10≦R<47 | ||||||

*1:Resistance tolerance ± 0.5% (D) of NRG1005 is available only at T10

◆Dimensions

| Type | Size (inch) |

L | W | a | b | t |

|---|---|---|---|---|---|---|

| NRG1005 | 0402 | 1.00±0.05 | 0.50±0.05 | 0.20±0.10 | 0.25±0.05 | 0.35±0.05 |

| NRG1608 | 0603 | 1.60±0.20 | 0.80+0.25/-0.20 | 0.30±0.20 | 0.30±0.20 | 0.40+0.15/-0.10 |

| NRG2012 | 0805 | 2.00±0.20 | 1.25+0.25/-0.20 | 0.40±0.20 | 0.40±0.20 | 0.40+0.15/-0.10 |

| NRG3216 | 1206 | 3.20±0.20 | 1.60±0.25 | 0.50±0.25 | 0.50±0.20 | 0.40+0.15/-0.10 |

(unit:mm)

◆Reliability specification

| Test items | Condition (test methods (MIL-PRF-55342/JIS C5201-1) | Standard |

|---|---|---|

| Short time overload | 2.5 x rated voltage*1, 5seconds | ±(0.5%+0.01Ω) |

| Life (biased) | 70℃, rated voltage*1, 90min on 30min off, 1000hours | ±(0.5%+0.05Ω) |

| High temperature high humidity | 85℃, 85%RH, 1/10 of rated power, 90min on 30min off, 1000hours | ±(0.5%+0.01Ω) |

| Temperature shock | -55℃(30min) ~ 125℃(30min) 1000cycles | ±(0.5%+0.01Ω) |

| High temperature exposure | 155℃, no bias, 1000hours | ±(0.5%+0.01Ω) |

| Resistance to soldering heat | 260±5℃, 10 seconds (reflow) | ±(0.05%+0.01Ω) |

*1 Rated voltage is given by E= √R x P E= rated voltage(V), R=nominal resistance value(Ω), P=rated power(W)

If rated voltage exceeds maximum voltage /element, maximum voltage/element is the rated voltage.

◆Reliability test data

○Biased life test

○High temperature high humidity (biased)

○Temperature shock

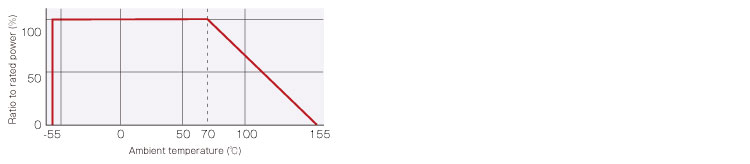

◆Derating Curve

Please feel free to contact us about products,

requesting documents and samples.

Products

-

-

Thin film surface mount resistors

- Thin film surface mount resistors TOP

- HRG series

- MRG series

- NRG series

- PRG series

- RG series

- RGA series

- RGT series

- RGV series

- RM series

- RMA series

- RR series

- RS series

- RT series

- URG series

- Current sensing surface mount resistors TOP

- KRL series (4 terminal type)

- KRL series (long-side terminal)

- KRL series (short-side terminal)

- PRL/RL series (long-side terminal)

- RL series (short-side terminal)

- YJP series

- High freguency surface mount components TOP

- ATF series

- ATS-FD series

- HPT series

- P*V series

- PAT series

- PAT series, W type

- PCS series

- PS series

- RFD series

-

Thin film surface mount resistors

Activity Contents

Technical Information

How to use chip resistors smartly

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

Standard Specification for surface mount chip resistors

- Recommended land patterns

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

Standard Specification for High frequency surface mount components

Smart usage of High Frequency Chip Components

Susumu Deutschland GmbH