-

Products

- Products Top

- New Products Infomation

- Selection Guide

- Product Catalogue

- Product Category

- Global Network

-

Technical

Information- Technical Information Top

-

How to use chip resistors smartly

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

- 8.Various methods of current sensing and advantage of current sensing resistors

- 9.Application and recommended usage of current sensing resistors

- Smart usage of High Frequency Chip Components

- Application Information

-

Product Technical Report

Standard Specification for surface mount chip resistors

- Recommended land patterns

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

Standard Specification for High frequency surface mount components

- Recommended reflow soldering profile

- Dimensions of the packaging tape

- Dimensions of the packaging reel

-

Technical FAQ

High Precision Thin Film Chip Resistors

- ・Part numbering

- ・Performance characteristics

- ・Quality, reliability

- ・Mounting, packaging

Current sensing chip resistors

- ・Part numbering

- ・Performance characteristics

- ・Quality, reliability

- ・Mounting, packaging

- Company Profile

-

QC and Environmental

Activities

- HOME

- Technical Information

- High Precision Thin Film Chip Resistors

Technical FAQ High Precision Thin Film Chip Resistors

| Q1 | What is your recommended product for 10kΩ, rated power 0.1W, and TCR is 25ppm/K ? |

|---|---|

| A1 | In RG series, size is 1608 (1.6mm x 0.8mm), code for TCR is P, code for tolerance is B, then, what you are looking for is: RG1608P-103-B-T5. T5 designates 5000, the quantity in a reel. |

| Q2 | How part numbers differ in RG series for high precision, standard and high power ? |

|---|---|

| A2 | There is no difference in part number for precision, standard or high power. This means even though they are the same products, depending on what voltage your application requires and how it relates to the rated power, you can choose one of the 3 conditions. Note that depending on the condition, maximum resistance drift rate is different in reliability tests. Please be sure you verify the reliability specification. |

| Q3 | Is quantity in a reel expressed in the part number? What is the unit of the packing ? |

|---|---|

| A3 | The quantity in a reel is expressed in the last 2 digits of the part number. However, it can change depending on product series and product size. Please consult each series part numbering system in our catalogue for details. |

| Q4 | Two element RM has resistance value in its part number. How about 3 element or more ? |

|---|---|

| A4 |

In 2 element RM, both resistance value are expressed in its part number. If 3 or more, part number designates circuitry type and special code for the custom part. Refer to RM series part numbering system. The standard marking on the chip is a dot and a bar shown as ① below. If custom code is added, it would be like ②. Contact us for other type of marking.

|

| Q5 | Can E96 series be expressed in 3 digits ? |

|---|---|

| A5 | In 1608 size, it is so small that it is difficult to mark on the products. In RG series, you can choose "no marking " or "simplified marking". Most users choose no marking. For simplified marking, refer to product technical report in this web site or catalogue. |

| Q1 | Can we use RG2012 with 1/4W ? |

|---|---|

| A1 | You can use it at 1/4W but it is in "high power "condition, and has to be 47Ω or higher. Specified maximum drift could be larger in some of the reliability tests. |

| Q2 | In RG 2012, what is the difference among 3 groups of rated power, precision, standard and high power ? |

|---|---|

| A2 | There is no difference in product part number even though there are 3 power ratings. Because rated power is different, the rated voltage, calculated from rated power, is also different. Reliability specification is also different. For details, please refer to the catalogue. |

| Q3 | By calculation, rated voltage exceeds element maximum voltage. Can I use it ? |

|---|---|

| A3 |

You cannot use products over element maximum voltage. Below the element maximum voltage, you can use the products at lower rated voltage given by the formula: Rated voltage: E = (R×P) E:rated voltage (V)、R:Rated resistance(Ω)、P:rated power (W) |

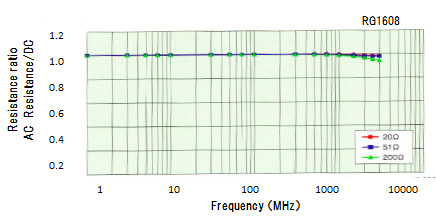

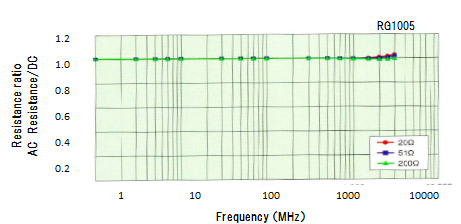

| Q4 | What is frequency performance of RG series ? |

|---|---|

| A4 | It depends on resistance value and product size. The higher the resistance value, the lower the resistance drift in very high frequency. The typical frequency characteristics are shown below. |

|

RG1608

RG1005 |

|

| Q5 | I am looking for the highest rated power product in 3216 size? What do you recommend ? |

|---|---|

| A5 |

We have two 1W precision 3216 size resisters and one 1.5W low resistance current sensor. The precision resistors are PRG (long side terminal) and HRG (short side terminal) and current sensors are KRL series. |

| Q1 | We are considering thin film resistors for automotive application. Do you have highly reliable products ? |

|---|---|

| A1 | AEC-Q200 compliant RG series offers +/-0.05% tolerance and +/-5ppm/oC TCR. This product's typical drift after 10000 hours of various reliability tests is less than +/-0.1%, extremely reliable. |

| Q2 | Are there anti-sulfur thin film resistors? |

|---|---|

| A2 | Susumu's products do not use any Ag in their terminals. Therefore they do not have any sulfur related issues. In addition, RG series employs inorganic passivation and extremely tolerant to moisture. |

| Q3 | Please recommend products with very small TCR and minimal drift at high and low temperature ? |

|---|---|

| A3 | URG series has +/-1ppm/oC TCR and extremely stable under low and high temperature. |

| Q4 | How should I read the MRG series' maximum pulse power limit? If the pulse's voltage is over the rated voltage, can the resistor tolerate it ? |

|---|---|

| A4 |

Rated voltage is given by: Rated voltage : E = (R×P) E: Rated voltage (V), R: Rated resistance(Ω), P: Rated power (W) In the chart showing maximum pulse power limit, X axis is pulse duration. In very short pulse, maximum power exceeds rated power. This means pulse voltage exceeds rated voltage. This maximum power limit is a reference. Please calculate average power and design with some margins. |

| Q1 | I want to know the recommended lad pattern for RG series |

|---|---|

| A1 | Product technical report lists recommended land patterns for all products. Please refer it. |

| Q2 | HRG series has higher power than other short side terminal products. Is there anything we should consider when mounting HRG series ? |

|---|---|

| A2 | HRG series have larger terminals in order to handle high power. Therefore, the land pattern also should be larger than other same size products. Please use it so that the terminal temperature should not exceed 155 degree(C) giving consideration to the board temperature. |

| Q3 | Cam we solder chip resistors with solder dipping ? |

|---|---|

| A3 | Yes, it is possible . Recommended condition is 10 seconds at 260 degree(C). |

| Q4 | What is the resistance drift by soldering ? |

|---|---|

| A4 | This film products show almost no change at all by soldering. RG series specification is +/-0.05%+0.01Ω. This depend on the products. Please refer to your purchase specification. |

| Q5 | Is the tape paper or embossed plastic? |

|---|---|

| A5 | It depend on the product size. Generally speaking, 2012 or smaller use paper tape and 3216 or larger use embossed tape. Some products use embossed tape for 2012 (ex. RM2012). For details please refer to the product technical report. |

Technical Information

-

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

- 8.Various methods of current sensing and advantage of current sensing resistors

- 9.Application and recommended usage of current sensing resistors

-

-

Standard Specification for surface mount chip resistors

- Recommended land patterns (soldering footprints)

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

-

Standard Specification for surface mount chip resistors

-

- High Precision Thin Film Chip Resistors Current sensing chip resistors

Please feel free to contact us about products,

requesting documents and samples.

Activity Contents

Technical Information

How to use chip resistors smartly

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

Standard Specification for surface mount chip resistors

- Recommended land patterns

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

Standard Specification for High frequency surface mount components

Smart usage of High Frequency Chip Components

Susumu Deutschland GmbH