-

Products

- Products Top

- New Products Infomation

- Selection Guide

- Product Catalogue

- Product Category

- Global Network

-

Technical

Information- Technical Information Top

-

How to use chip resistors smartly

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

- 8.Various methods of current sensing and advantage of current sensing resistors

- 9.Application and recommended usage of current sensing resistors

- Smart usage of High Frequency Chip Components

- Application Information

-

Product Technical Report

Standard Specification for surface mount chip resistors

- Recommended land patterns

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

Standard Specification for High frequency surface mount components

- Recommended reflow soldering profile

- Dimensions of the packaging tape

- Dimensions of the packaging reel

-

Technical FAQ

High Precision Thin Film Chip Resistors

- ・Part numbering

- ・Performance characteristics

- ・Quality, reliability

- ・Mounting, packaging

Current sensing chip resistors

- ・Part numbering

- ・Performance characteristics

- ・Quality, reliability

- ・Mounting, packaging

- Company Profile

-

QC and Environmental

Activities

- HOME

- Technical Information

- 2.Manufacturing methods and characteristics of thin film resistors

2.Manufacturing methods and characteristics of thin film resistors

2.1 Resistive materials and shapes (thin film chip resistor)

Resistive material

There are numerous resistive materials, Susumu uses the following two materials

Metal thin film →precision thin film chip resistors

Metal foil →current sensing chip resistors

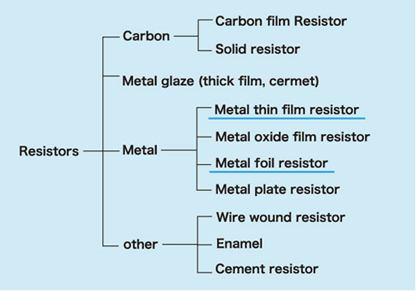

Shapes of resistors

Resistors come in many different shapes. Susumu focus on chip resistors.

Chip resistors

Thin film chip resistors

Thick film resistors

Radial lead resistors

Axial lead resistors

2.2 Characteristics of thin film and how to deposit it

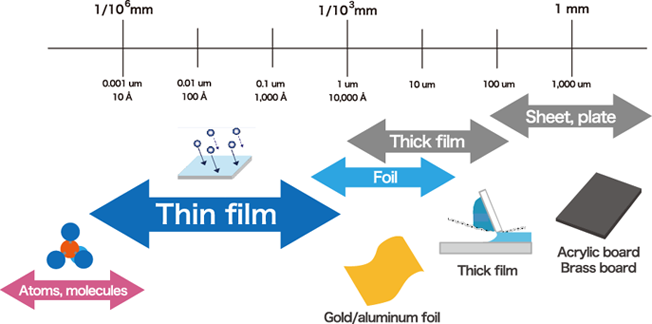

Thin film? How thick is it?

There are many methods to make things thin. Some examples are shown here. Susumu manufactures resistors from thin film using deposition technologies that make film thickness 1um and down to a few Å.

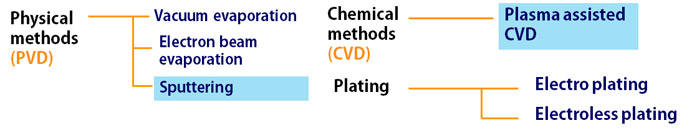

Thin film deposition methods

In electronics, there are many thin film deposition methods. Susumu uses several methods depending on the products and materials. Two main methods, sputtering and plasma assisted chemical vapor deposition are explained here.

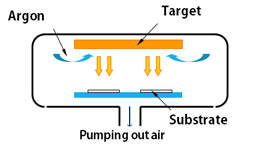

Sputtering method

Argon ions, created by glow discharge under vacuum, sputter out target (materials for the thin film) atoms/molecules. These target atoms/molecules adhere to the substrates and form thin film. This method is ideal for depositing metal alloy thin films and high melting point materials.

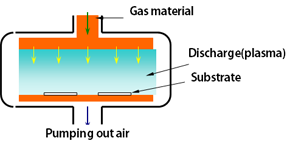

Plasma assisted Chemical Vapor Deposition (PCVD)

In plasma (glow discharge), thin film precipitate after a series of chemical reaction. Thin film is formed under relatively low temperature. Any materials, organic or inorganic, that can be made into gas compounds can be deposited.

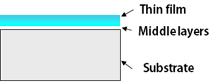

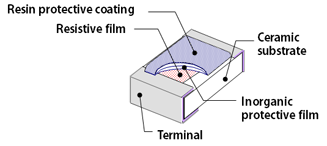

From thin film to resistor

Thin films are deposited with these methods. Thin film technology is not only used for resistors but also used to create internal terminals and protective coating layers.

Technical Information

-

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

- 8.Various methods of current sensing and advantage of current sensing resistors

- 9.Application and recommended usage of current sensing resistors

-

-

Standard Specification for surface mount chip resistors

- Recommended land patterns (soldering footprints)

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

-

Standard Specification for surface mount chip resistors

-

- High Precision Thin Film Chip Resistors Current sensing chip resistors

Please feel free to contact us about products,

requesting documents and samples.

Activity Contents

Technical Information

How to use chip resistors smartly

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

Standard Specification for surface mount chip resistors

- Recommended land patterns

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

Standard Specification for High frequency surface mount components

Smart usage of High Frequency Chip Components

Susumu Deutschland GmbH