-

Products

- Products Top

- New Products Infomation

- Selection Guide

- Product Catalogue

- Product Category

- Global Network

-

Technical

Information- Technical Information Top

-

How to use chip resistors smartly

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

- 8.Various methods of current sensing and advantage of current sensing resistors

- 9.Application and recommended usage of current sensing resistors

- Smart usage of High Frequency Chip Components

- Application Information

-

Product Technical Report

Standard Specification for surface mount chip resistors

- Recommended land patterns

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

Standard Specification for High frequency surface mount components

- Recommended reflow soldering profile

- Dimensions of the packaging tape

- Dimensions of the packaging reel

-

Technical FAQ

High Precision Thin Film Chip Resistors

- ・Part numbering

- ・Performance characteristics

- ・Quality, reliability

- ・Mounting, packaging

Current sensing chip resistors

- ・Part numbering

- ・Performance characteristics

- ・Quality, reliability

- ・Mounting, packaging

- Company Profile

-

QC and Environmental

Activities

- HOME

- Technical Information

- 5.Trimmable chip resistors and altering resistive values

5.Trimmable chip resistors and altering resistive values

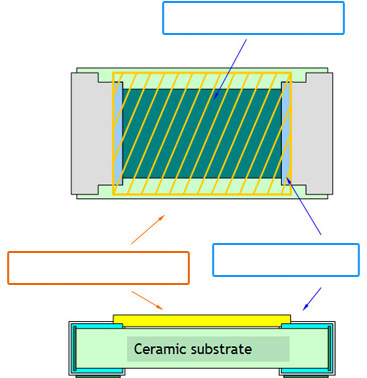

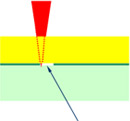

5.1 The structure of trimmable chip resistors and how they work

Thin film resistor

Glass film(CVDed)

Terminal film

YAG laser

Glass film

Substrate

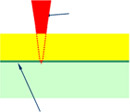

Thin film resistor

YAG laser applies energy to the thin film resistive element without damaging the glass film

Oxidized film

(translucent)

With the energy, the metal film acquires oxygen from the glass and change itself to metal oxide. Metal resistive film becomes insulator and trimming is done.

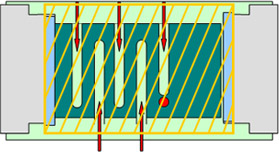

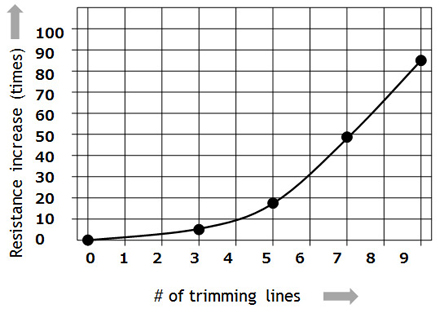

5.2 Adjusting resistor in trimmable chip resistors

Trimming (conceptual drawing)

This is one example. Actual resistance change depends on products and trimming machines.

Trimmable chip resistors features:

- 1.One trimmable chip can be trimmed into wide range of resistive values

- 2.Glass protective layer stays intact and continues protecting resistors after trimming

- 3.Metal to metal oxide change by trimming makes it possible to adjust precisely.

- 4.The characteristics of metal thin film resistors remain after trimming.

Technical Information

-

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

- 8.Various methods of current sensing and advantage of current sensing resistors

- 9.Application and recommended usage of current sensing resistors

-

-

Standard Specification for surface mount chip resistors

- Recommended land patterns (soldering footprints)

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

-

Standard Specification for surface mount chip resistors

-

- High Precision Thin Film Chip Resistors Current sensing chip resistors

Please feel free to contact us about products,

requesting documents and samples.

Activity Contents

Technical Information

How to use chip resistors smartly

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

Standard Specification for surface mount chip resistors

- Recommended land patterns

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

Standard Specification for High frequency surface mount components

Smart usage of High Frequency Chip Components

Susumu Deutschland GmbH