-

Products

- Products Top

- New Products Infomation

- Selection Guide

- Product Catalogue

- Product Category

- Global Network

-

Technical

Information- Technical Information Top

-

How to use chip resistors smartly

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

- 8.Various methods of current sensing and advantage of current sensing resistors

- 9.Application and recommended usage of current sensing resistors

- Smart usage of High Frequency Chip Components

- Application Information

-

Product Technical Report

Standard Specification for surface mount chip resistors

- Recommended land patterns

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

Standard Specification for High frequency surface mount components

- Recommended reflow soldering profile

- Dimensions of the packaging tape

- Dimensions of the packaging reel

-

Technical FAQ

High Precision Thin Film Chip Resistors

- ・Part numbering

- ・Performance characteristics

- ・Quality, reliability

- ・Mounting, packaging

Current sensing chip resistors

- ・Part numbering

- ・Performance characteristics

- ・Quality, reliability

- ・Mounting, packaging

- Company Profile

-

QC and Environmental

Activities

- HOME

- Technical Information

- 3.Performance characteristics of thin film resistors

3.Performance characteristics of thin film resistors

3.1 Advantage and performance characteristics of Susumu thin film resistors

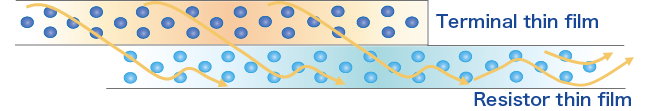

Thin film resistors, made of deposited (such as sputtered) homogeneous metal thin film, have smooth electron flow, small temperature coefficient of resistance, and long term stability and fit for high precision application.

Monolithic structure with smooth electron flow

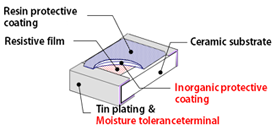

In order to further improve moisture tolerance, our terminals also have innovative thin film structure. Therefore, Susumu’s RG series are extremely robust, reliable and stable and widely used for automotive electronics.

Double layered protective coating

・Inorganic film

Innovative moisture tolerant terminal

3.2 Difference between thin film resistors and thick film resistors

Thin film resistors, due to their continuous even metal structure, compared to thick film resistors, have smaller resistance tolerance and temperature coefficient of resistance (TCR)

| Performance | Typical thick film resistors | Susumu thin film resistors |

|---|---|---|

| Resistive tolerance | +/- 0.5%, 1% (precision) |

+/-0.01%, 0.05%, 0.1%, 0.5% (high precision) |

| Temperature coefficient of resistance | ±25ppm,±50ppm,100ppm (large TCR) |

+/-1ppm, 5ppm, 10ppm, 25ppm (small TCR) |

| Current noise | Less than +10dB | Less than -20dB |

Resistance Tolerance and Temperature Coefficient of Resistance (TCR)

Resistance tolerance shows possible error in room temperature, and TCR shows resistance change /oC in ppm within a specified temperature range. Chart below illustrates the resistance change of TCR ±10ppm, ±25ppm. TCR range depend on each specification. The resistance change does not have to be the same direction (negative or positive)

<Resistance tolerance>

・Unit (%) ;±0.1(%) is shown in the chart.

・Tolerance is designated by the following codes.

± 0.01% : (L) ± 0.02% : (P)

± 0.05% : (W) ± 0.1% : (B)

± 0.5% : (D)

<TCR>

・Unit(ppm/℃);±10 , 25

(ppm/℃) are shown in the chart

・TCR is designated by the codes as follows

± 1ppm : (K) ± 2ppm : (L)

± 5ppm : (V) ± 10ppm : (N)

± 25ppm : (P) ± 50ppm : (Q)

3.3 Major characteristics of thin film resistors

Rated Power

Maximum power that can be continuously applied in an ambient temperature. It differs depending on size. Long side terminal and widened terminal products excel in heat dissipation and can handle higher power for the same size, enabling miniaturization or reduction of components.

Rated Voltage

Maximum DC voltage or AC voltage (effective value)that can be continuously applied in an ambient temperature given by the following formula.

E=R×P

E:Rated voltage(V), R:Resistance(Ω), P:Rated power(W)

however, If E is larger than the maximum element voltage, the maximum element voltage is the rated voltage.

Maximum element voltage

Maximum DC or AC voltage(effective value) that can be continuously applied to the resistor.

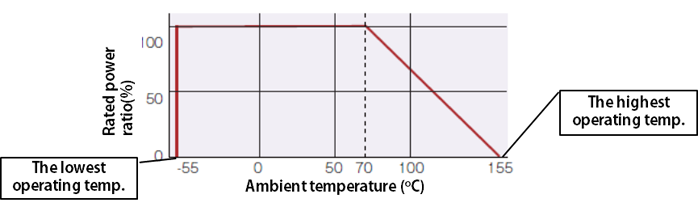

Operating temperature range

The temperature range where, by design, the resistor can be used continuously, defined by the lowest operating temperature and the highest operating temperature.

| The lowest operating temperature | : | The lowest temperature where the resistor can be used continuously. |

|---|---|---|

| The highest operating temperature | : |

The highest temperature where the resistor can be used continuously. The point where derating curve intersects X axis (zero power) |

Power derating curve

The curve that shows the operating temperature range and maximum power at each temperature point. This curve is dependent of the different product series.

Technical Information

-

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

- 8.Various methods of current sensing and advantage of current sensing resistors

- 9.Application and recommended usage of current sensing resistors

-

-

Standard Specification for surface mount chip resistors

- Recommended land patterns (soldering footprints)

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

-

Standard Specification for surface mount chip resistors

-

- High Precision Thin Film Chip Resistors Current sensing chip resistors

Please feel free to contact us about products,

requesting documents and samples.

Activity Contents

Technical Information

How to use chip resistors smartly

- 1.Basic knowledge of resistors

- 2.Manufacturing methods and characteristics of thin film resistors

- 3.Performance characteristics of thin film resistors

- 4.High precision and high reliability

- 5.Trimmable chip resistors and altering resistive values

- 6.Application and recommended usage of thin film chip resistors

- 7.Application and recommended usage of small high power thin film ship resistors

Standard Specification for surface mount chip resistors

- Recommended land patterns

- Recommended reflow and flow soldering profile

- Dimensions of the packaging reel

- Dimensions of the packaging tape

Standard Specification for High frequency surface mount components

Smart usage of High Frequency Chip Components

Susumu Deutschland GmbH